Essential Insights into Durable Seawater Valves for Industrial Applications

In the industrial equipment sector, particularly within the domain of valves and related components, the significance of durable seawater valves cannot be overstated. These specialized valves are designed to operate in harsh marine environments where exposure to saltwater and other corrosive elements can rapidly degrade standard materials. Understanding the characteristics and benefits of durable

In the industrial equipment sector, particularly within the domain of valves and related components, the significance of durable seawater valves cannot be overstated. These specialized valves are designed to operate in harsh marine environments where exposure to saltwater and other corrosive elements can rapidly degrade standard materials. Understanding the characteristics and benefits of durable seawater valves is essential for industries involved in maritime operations, offshore drilling, and water management systems.

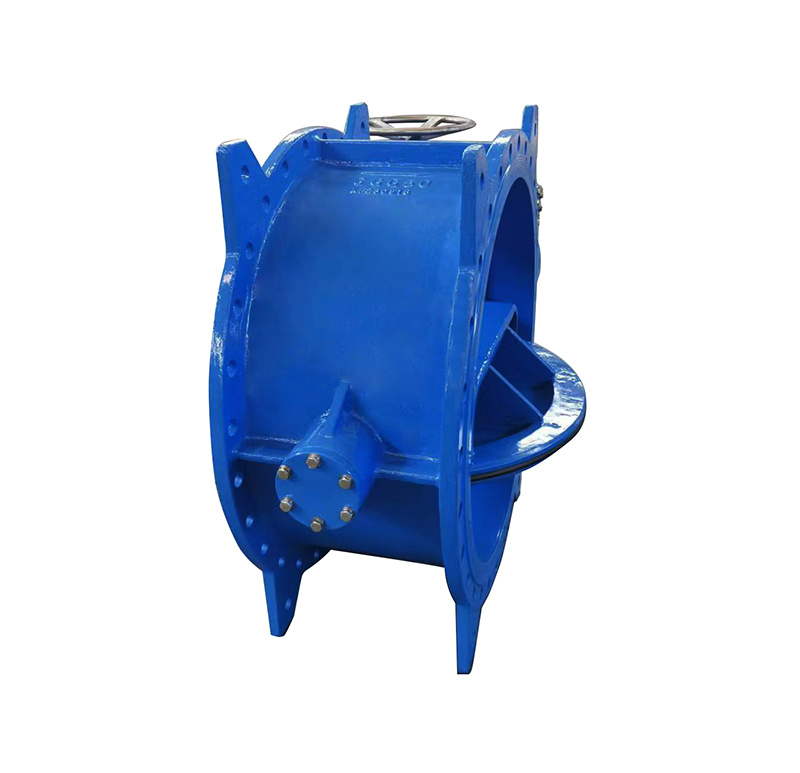

The primary focus of durable seawater valves is their construction, which typically employs corrosion-resistant materials such as duplex stainless steel, titanium, or specialized alloys. These materials are engineered to withstand the chemical and physical stresses imposed by seawater, ensuring the valve maintains its integrity and functionality over extended periods. When selecting a seawater valve, it is critical to consider the specific environmental conditions it will face, including temperature variations, flow rates, and pressure levels.

Durable seawater valves also incorporate advanced sealing technologies to prevent leaks and ensure optimal performance. These seals are often made from high-performance elastomers or PTFE, which provide excellent resistance to saltwater and other corrosive agents. Additionally, the design of the valve body and components plays a crucial role in mitigating the risk of fouling and buildup, which can impede flow and reduce efficiency.

Installation and maintenance practices are vital for the longevity of durable seawater valves. Regular inspections should be conducted to identify any signs of wear or damage, particularly in high-flow applications. Implementing a proactive maintenance strategy can significantly enhance the operational lifespan of these valves, ultimately contributing to lower downtime and repair costs.

Furthermore, the role of durable seawater valves extends beyond mere functionality; they are also critical for ensuring safety in marine operations. A failure in the valve system can lead to catastrophic consequences, including leaks that may pose environmental hazards. Thus, investing in high-quality, durable seawater valves is not only a matter of operational efficiency but also a key element in regulatory compliance and environmental stewardship.

In conclusion, understanding the importance of durable seawater valves in industrial applications is crucial for businesses operating in marine environments. By focusing on material selection, design features, and maintenance practices, companies can enhance the reliability and functionality of their valve systems, thereby ensuring smooth operations in challenging conditions. As industries continue to evolve and adapt to new challenges, the demand for advanced durable seawater valves will remain a significant factor in achieving operational excellence.

The primary focus of durable seawater valves is their construction, which typically employs corrosion-resistant materials such as duplex stainless steel, titanium, or specialized alloys. These materials are engineered to withstand the chemical and physical stresses imposed by seawater, ensuring the valve maintains its integrity and functionality over extended periods. When selecting a seawater valve, it is critical to consider the specific environmental conditions it will face, including temperature variations, flow rates, and pressure levels.

Durable seawater valves also incorporate advanced sealing technologies to prevent leaks and ensure optimal performance. These seals are often made from high-performance elastomers or PTFE, which provide excellent resistance to saltwater and other corrosive agents. Additionally, the design of the valve body and components plays a crucial role in mitigating the risk of fouling and buildup, which can impede flow and reduce efficiency.

Installation and maintenance practices are vital for the longevity of durable seawater valves. Regular inspections should be conducted to identify any signs of wear or damage, particularly in high-flow applications. Implementing a proactive maintenance strategy can significantly enhance the operational lifespan of these valves, ultimately contributing to lower downtime and repair costs.

Furthermore, the role of durable seawater valves extends beyond mere functionality; they are also critical for ensuring safety in marine operations. A failure in the valve system can lead to catastrophic consequences, including leaks that may pose environmental hazards. Thus, investing in high-quality, durable seawater valves is not only a matter of operational efficiency but also a key element in regulatory compliance and environmental stewardship.

In conclusion, understanding the importance of durable seawater valves in industrial applications is crucial for businesses operating in marine environments. By focusing on material selection, design features, and maintenance practices, companies can enhance the reliability and functionality of their valve systems, thereby ensuring smooth operations in challenging conditions. As industries continue to evolve and adapt to new challenges, the demand for advanced durable seawater valves will remain a significant factor in achieving operational excellence.