Product Classification

Contact

E-mail:znzdvalve@gmail.com

Address:No. 1, Jinniu Road, Xingyang City, Henan Province, China

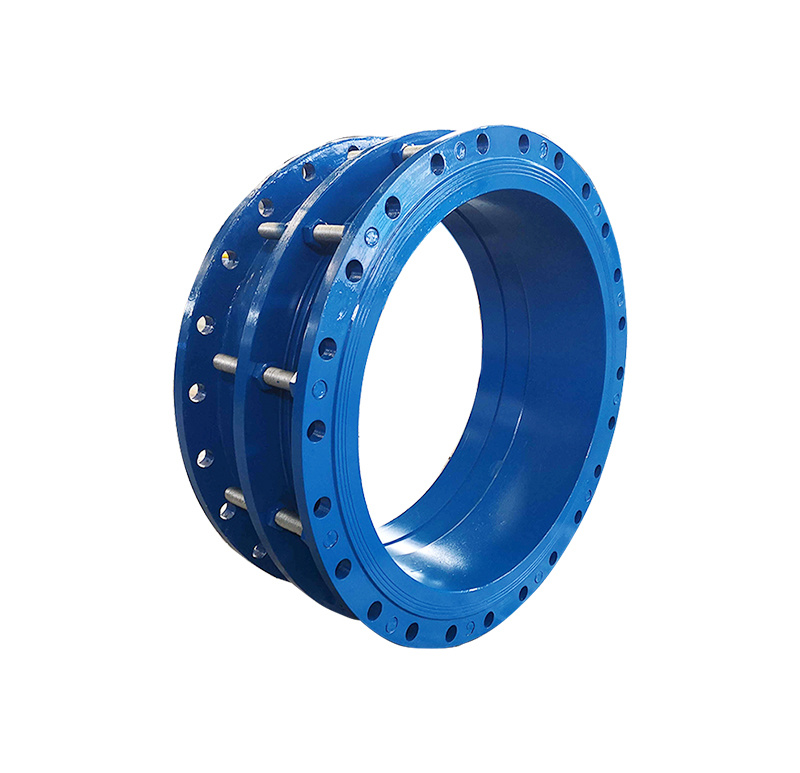

Electric Hemispherical Valve

Categories:

Eccentric Half Ball Valve

Email: znzdvalve@gmail.com

It can be customized according to different needs.

Product Overview

Electric Eccentric Semi-Globe Valve is a high performance cut-off valve, combining the advantages of eccentric structure and electric actuator. Its main features include:

1. High efficiency and energy saving: straight-through flow path design, small flow resistance, suitable for large flow rate transportation.

2. Reliable sealing performance: eccentric structure design, the sealing surface closely fits when closing, and the sealing surface is completely disengaged when opening, reducing wear and tear.

3. Easy operation: electric actuator can realize remote control and automatic operation.

4. Convenient maintenance: top-mounted structure, easy to replace and maintain damaged parts.

Scene of use

1.Municipal water supply and drainage system

Application scenario: urban water supply pipeline, drainage pipeline, sewage treatment plant, etc.

2.Long-distance water transfer project

Application scenes: long-distance water transfer pipelines, water conservancy projects, etc.

3.Sewage treatment system

Application Scenario: sewage transportation pipeline, sludge treatment pipeline, etc.

4.Industrial piping system

Application scenarios: chemical, pharmaceutical, paper making, food processing and other industries.

5.Energy system

Application scenarios: natural gas, gas, steam and other energy transportation pipelines.

6.Water treatment system

Application Scenario: dam bottom release valve, city heating and heating system, tap water system, etc.

7. Pump delivery system

Application scenario: pressurized system, central air-conditioning system, etc.

Applicable media

1.Liquid medium

Clear water, raw water (including mud and sand), sewage, seawater, steam water, oil (such as crude oil, heavy oil), pulp, solution, alumina powder, coal dust, coal ash, slag and so on.

2. Gas media

Natural gas, gas, liquefied gas, steam, etc..

3. Solid-liquid mixed media

Suitable for liquid, solid two-phase mixed flow or liquid transportation in the chemical reaction of crystallization or scaling of industrial pipeline transportation.

Temperature of use

1.Soft seal electric eccentric half ball valve

Applicable temperature range: -10 ℃ to 100 ℃.

Seal ring material: nitrile rubber (NBR), EPDM, fluorine rubber (FKM) and so on.

2.Hard seal electric eccentric half ball valve

Applicable temperature range: -29℃ to 540℃.

Sealing surface material: stainless steel (such as 304, 316), hard alloy, etc.

V. Material

Valve body material

Ductile iron (GGG45): good strength and toughness, suitable for low and medium pressure conditions.

Carbon steel (such as WCB): suitable for higher pressure and temperature conditions.

Valve seat material

Stainless steel (such as 304, 316): strong corrosion resistance, suitable for corrosive media.

Cemented carbide: for hard sealing conditions, can withstand higher temperatures and pressures.

Valve flap (ball) material

Stainless steel (such as 304, 316): strong corrosion resistance, smooth surface, reduce the medium on the sealing surface of the abrasion.

Carbon steel (such as WCB): high strength, lower cost, suitable for non-corrosive media.

Seal ring material

Nitrile rubber (NBR): good oil resistance, wear resistance, suitable for oil-containing media and water media.

Fluorine rubber (FPM): high temperature resistance, chemical resistance, suitable for strong corrosive media.

Polytetrafluoroethylene (PTFE): high temperature resistance, chemical corrosion resistance, low coefficient of friction, excellent sealing performance.

EPDM: good water resistance, strong aging resistance, suitable for clear water and weak acid and alkali media.

Valve stem material

Stainless steel (such as 20Cr13, 304, 316): strong corrosion resistance, high strength, suitable for use with valve body and valve flap materials.

Electric actuator

Shell material: aluminum alloy or stainless steel, strong corrosion resistance.

Motor: high torque motor, suitable for frequent opening and closing conditions.

Control unit: support a variety of control signals, such as 4-20mA, switching signals, etc., which can realize remote control and automation operation.

Implementation standards

GB/T 12234-2019

EN 1092-1:2001

ANSI B16.34

API 600

API 602

API 603: Cast Iron and Cast Steel Valves

API 6D: “Pipeline Valves

Key words:

Previous:

Next:

Previous:

Next:

Related accessories

Product Brochure

Related Products

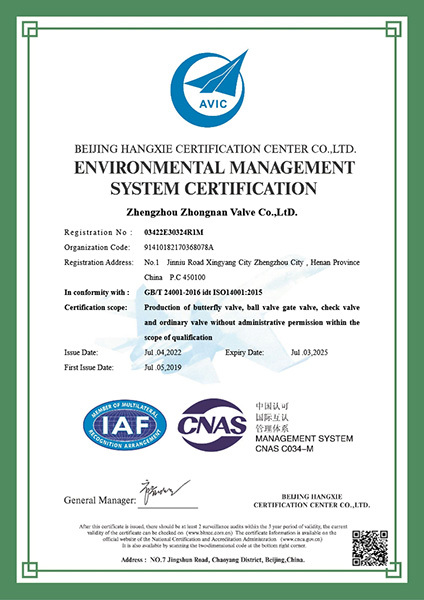

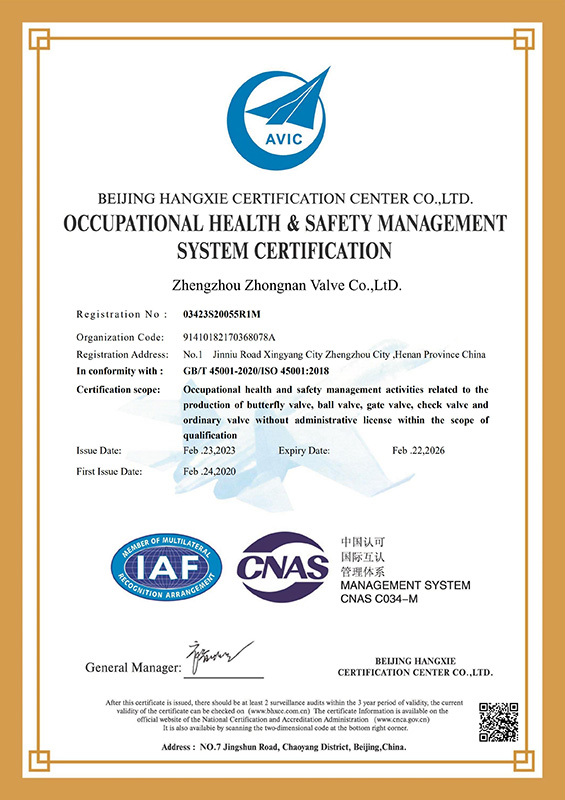

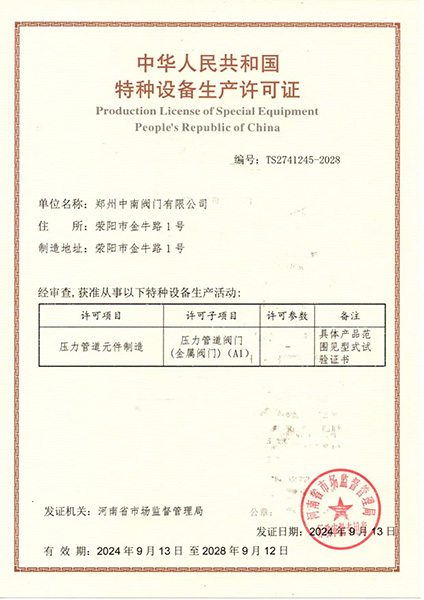

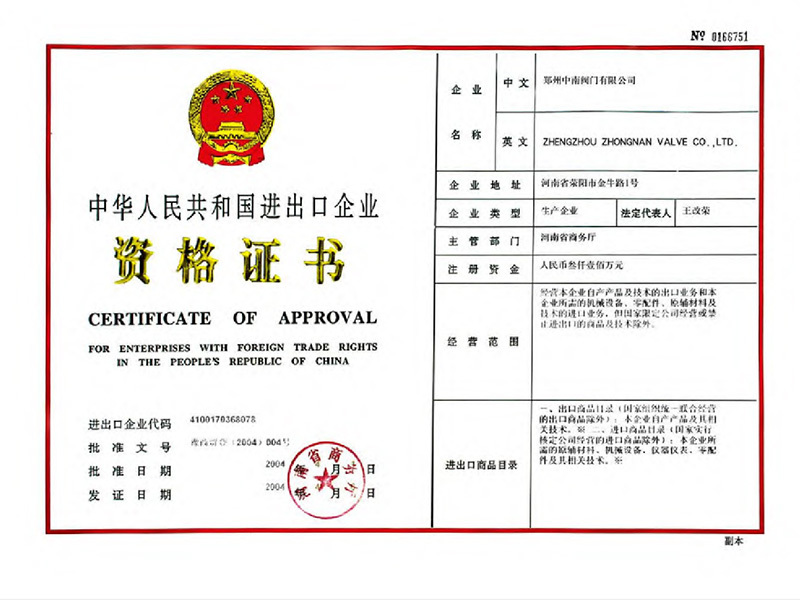

Honour

Get A Quote

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible