Product Classification

Contact

E-mail:official@zzvalves.com

Address:No. 1, Jinniu Road, Xingyang City, Henan Province, China

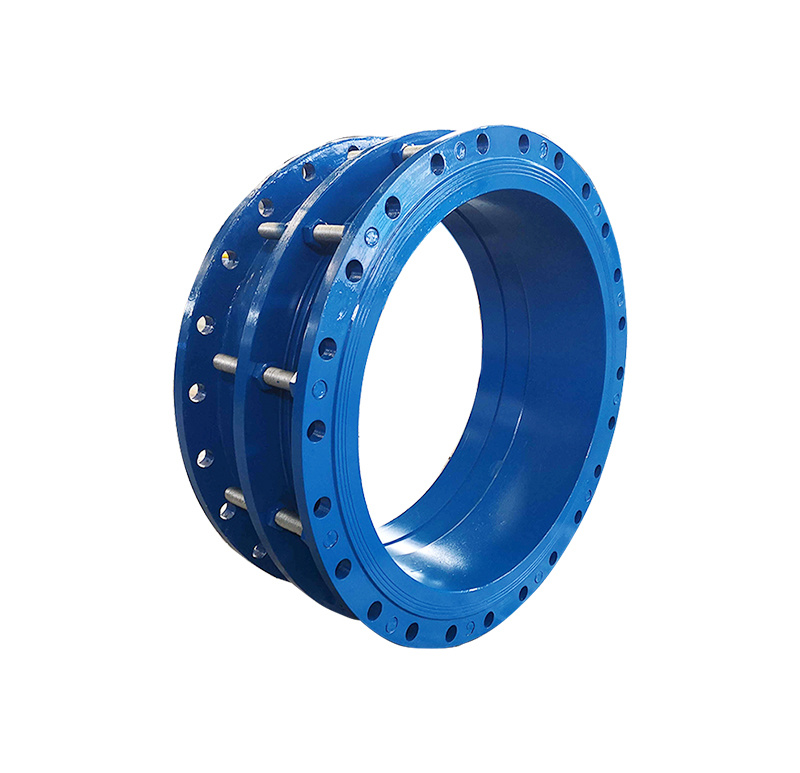

Full Bore Horizontal Ball Valve

Categories:

Full Bore Horizontal Hemispherical Valves

Email: official@zzvalves.com

We will respond to your inquiry within 5 minutes.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Can be customized according to your needs.

Product Features:

1. Excellent Flow Characteristics

Full Bore Design: The flow path of the full bore horizontal hemispherical ball valve is fully aligned with the pipeline, with no contraction or expansion in the flow path, resulting in low fluid resistance, enabling large flow and unobstructed flow.

Low Head Loss: When the valve is open, the flow path is smooth with minimal head loss, suitable for scenarios requiring efficient fluid transport.

2. Reliable Sealing Performance

Eccentric Structure: Featuring a double eccentric design, the valve has a tighter sealing function the more it is closed, ensuring reliable sealing performance. After opening, the sealing surface completely disengages to protect it from damage.

Self-Cleaning Function: When the ball moves away from the seat, fluid flows evenly along the sealing surface of the ball, washing away deposits on the sealing surface to achieve self-cleaning.

3. Easy Operation and Maintenance

Top-Mounted Structure: When replacing or repairing damaged opening and closing parts, there is no need to remove the entire valve from the pipeline, making it convenient and quick.

Online Maintenance: Supports online replacement of seals, enabling pressure-maintained opening and closing, reducing maintenance costs.

Low Operating Torque: The valve has a low opening and closing torque, making operation easy and suitable for frequent opening and closing scenarios.

4. Strong Applicability

Bidirectional Sealing: Suitable for both forward and reverse conditions, achieving bidirectional sealing, applicable to circulating water and various special conditions.

Wear-Resistant Design: The knife-edge design at the ball crown can cut debris, and the bidirectional floating seat can automatically compensate for wear on the sealing surface, further improving sealing reliability.

5. Economical and Energy-Saving

Energy Saving and Consumption Reduction: Due to low head loss, it can significantly reduce the energy consumption of pump units. For example, after a water plant used a full bore eccentric hemispherical valve, the pressure before the valve dropped by 4.33%, head loss decreased by 90.8%, saving nearly 87,900 yuan per pump unit annually.

Long Service Life: The optimized sealing structure and eccentric design reduce wear on the sealing surface, extending valve life and lowering maintenance frequency.

6. Small Footprint

Short Structural Length: The short structural length of the reduced-diameter hemispherical ball valve greatly saves installation space.

The full bore horizontal hemispherical ball valve is widely used in municipal water supply and drainage, long-distance water diversion, sewage treatment, industrial pipelines, and other scenarios requiring high efficiency, reliability, and low maintenance, and can be customized according to different needs.

Applicable Media

Liquid Media: Including clean water, raw water (containing sediment), sewage, seawater, steam water, oils (such as crude oil, heavy oil), slurry, solutions, alumina powder, coal powder, coal ash, slag, etc.

Gas Media: Such as natural gas, coal gas, liquefied gas, steam, etc.

Solid-Liquid Mixed Media: Suitable for industrial pipeline transport of liquid-solid two-phase mixtures or liquid transport in chemical reactions involving crystallization or scaling.

Usage Scenarios

Industrial Pipeline Systems: Can be used in pipeline systems transporting media containing particles, fibers, slurry, etc., especially suitable for high flow velocity and scaling-prone conditions.

Water Treatment Systems: Suitable for dam bottom drainage valves and control valves, urban heating systems, tap water systems, etc.

Energy Systems: Such as natural gas systems, gas systems, steam systems, etc.

Chemical Systems: Suitable for pipelines transporting corrosive media such as acids and alkalis.

Pumping Systems: Such as pressurization systems, central air conditioning systems, etc.

Component Materials

1. Valve Body Material

Ductile Iron: Has good strength and toughness, suitable for low to medium pressure conditions.

2. Valve Seat Material

Stainless Steel: Suitable for corrosive media.

3. Valve Stem: Usually stainless steel.

4. O-Ring: Stainless steel.

Operating Temperature

Wide applicable temperature range, generally from 0°C to 80°C.

Standards Adopted

Complies with GB, GB/T, EN, DIN, ANSI, API and other standards.

Key words:

Related accessories

Product Brochure

Related Products

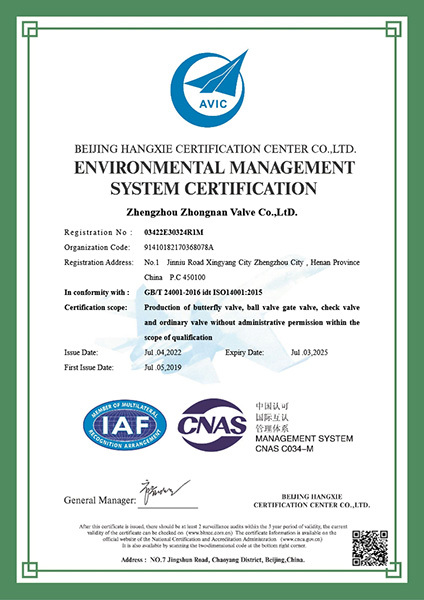

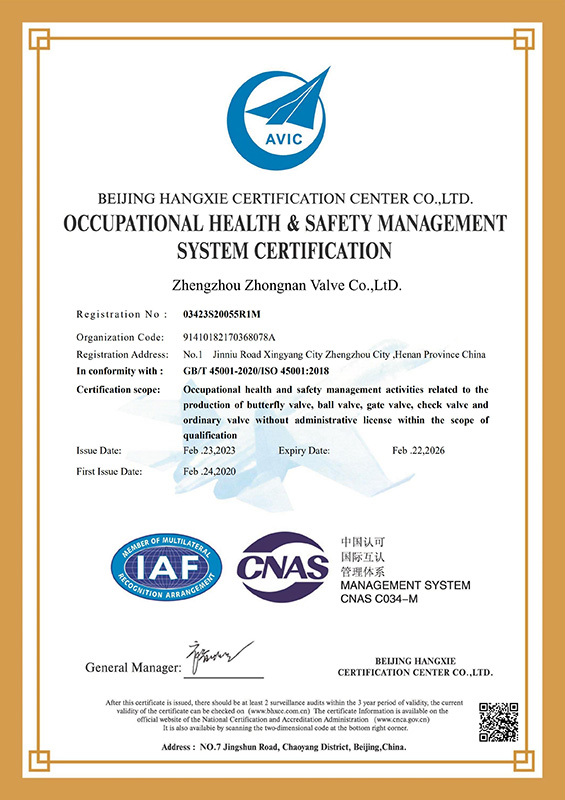

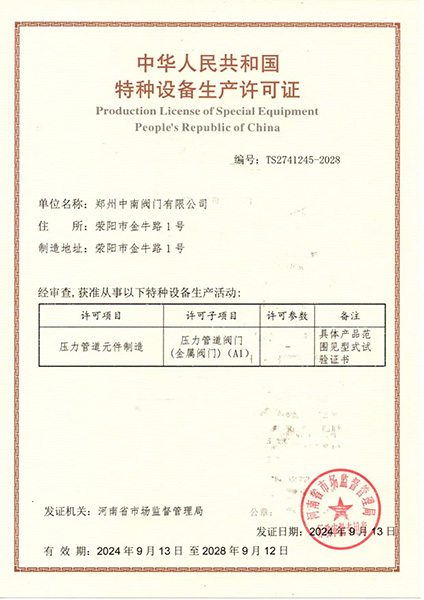

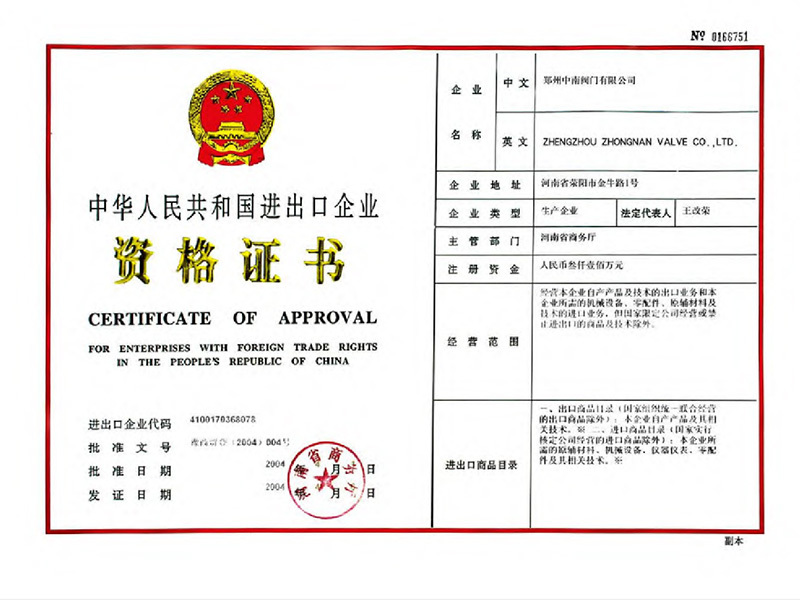

Honour