Product Classification

Contact

E-mail:official@zzvalves.com

Address:No. 1, Jinniu Road, Xingyang City, Henan Province, China

Rotary ball valve

Categories:

Rotary Ball Valve

Email: official@zzvalves.com

We will respond to your inquiry within 5 minutes.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible

Can be customized according to your needs.

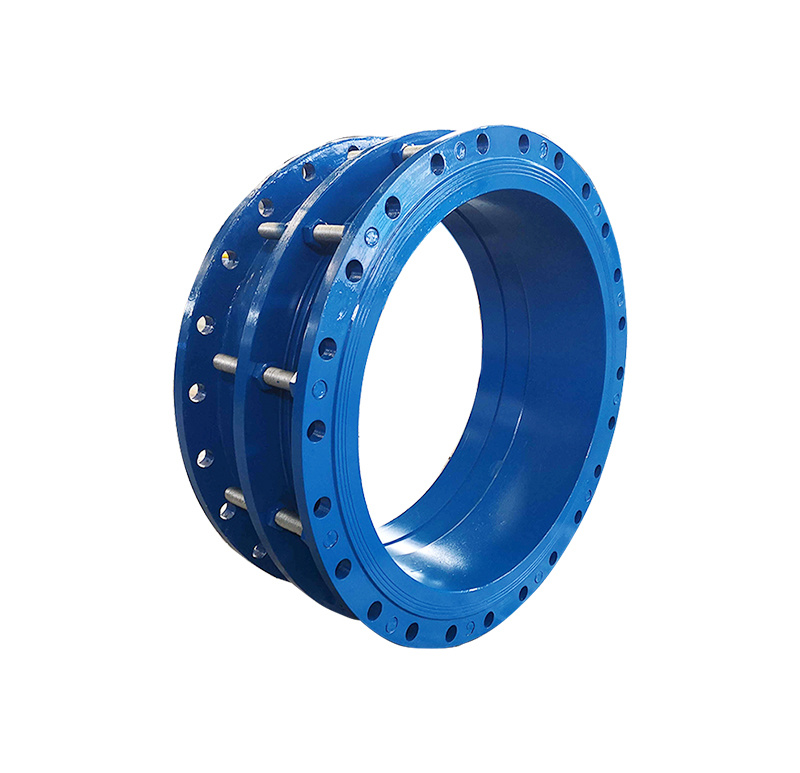

The bi-directional metal-sealed rotary ball valve is a new energy-saving product developed by Zhongnan in Zhengzhou. This product adopts the structural length of a butterfly valve, a double eccentric structure, and a spherical sealing pair. The valve stem is driven to rotate 90° by the driving device, synchronously rotating 90° with the driving opening and closing component (valve plate) to achieve valve opening and closing.

The metal-sealed rotary ball valve has reliable sealing, flexible operation, low maintenance costs, and is widely used in industries such as petroleum, petrochemical, chemical, electric power, mining, thermal power, environmental protection, metallurgy, papermaking, and municipal engineering for water supply pipelines, heating pipelines, and process pipelines. It features good sealing performance, bi-directional shutoff, compact size, light weight, can be installed in any direction, is adjustable, wear-resistant, suitable for media containing solid particles, and can be customized according to different requirements.

Product Features

Resin Sand Casting Process

The valve body and valve plate castings use resin sand casting technology, ensuring not only reliable casting quality but also clear and beautiful casting surface contours with high dimensional accuracy.

Double Eccentric Structure Design

Using the double eccentric wedge principle, the opening, closing, and adjustment are achieved through a transmission mechanism. The wedge tightens, and both the valve seat sealing surface and valve sealing surface are metal-faced ring hard contact seals. When closing, the valve plate's spherical surface gradually moves along the valve seat, providing a scraping function that effectively removes scale and obstacles, scraping off solid particles to achieve reliable sealing.

Bi-directional Sealing

The sealing surface of the bi-directional pressure metal hard-sealed rotary ball valve is made of hard alloy. The valve sealing surface is an eccentric spherical surface, and the seat sealing surface is a spherical sealing pair structure, forming a double seal with excellent bi-directional pressure sealing. Utilizing the eccentric spherical surface and reverse movement of the valve seat achieves good sealing. When the valve seat is subjected to back pressure, it automatically presses against the ball body; the higher the pressure, the greater the thrust, thus achieving excellent reverse sealing. The sealing pair forms a tangential seal with a suspended scraping and cutting function. The valve seat is a floating structure with automatic central positioning and wear compensation, ensuring reliable sealing performance, wear resistance, and erosion resistance. For nominal diameters ≤900, the rotary ball valve's valve stem and valve disc use spline connections to ensure firm and reliable connection. The valve shaft adopts an upper and lower half-shaft structure to reduce fluid resistance.

Metal Sealing

The sealing pair uses metal hard sealing. Depending on different working conditions, various types of hard alloys can be embedded and surfacing welded on the sealing surfaces of the valve plate and valve seat to meet requirements for wear resistance, corrosion resistance, erosion resistance, and media containing solid particles.

Short Structure

The structural length of the rotary ball valve adopts the structural length of the national standard butterfly valve, resulting in a compact size, light weight, and small installation space.

Easy Maintenance

If the sealing effect deteriorates, the user can remove the compression ring and replace or repair the valve seat to achieve the same sealing effect as a new valve.

Convenient Operation

Quick opening and closing, requiring only a 90° rotation from fully open to fully closed. Combined with electric, pneumatic, or hydraulic devices, remote centralized control can be realized.

Long Service Life

During the opening and closing process, the rotary ball valve can quickly disengage the sealing pair, greatly reducing wear between sealing surfaces. The sealing pair experiences no friction during operation, resulting in a long service life.

Applicable Media

Liquid media: water, sewage, oil, slurry, solution, acid, alkali, salt, and other weakly corrosive media.

Gas media: air, steam, gases, etc.

Solid-liquid mixed media: suitable for liquid transport in industrial pipelines involving two-phase liquid-solid mixtures or chemical reaction crystallization or scaling.

Operating Temperature

Applicable temperature range is -40℃ to 600℃.

Standards Adopted

Complies with GB, GB/T, EN, DIN, ANSI, API and other standards.

Key words:

Related accessories

Product Brochure

Related Products

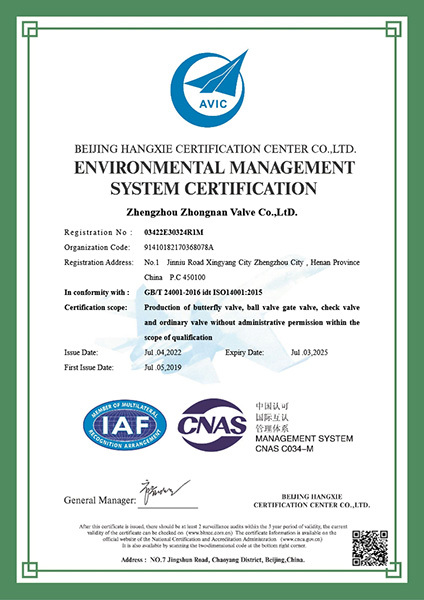

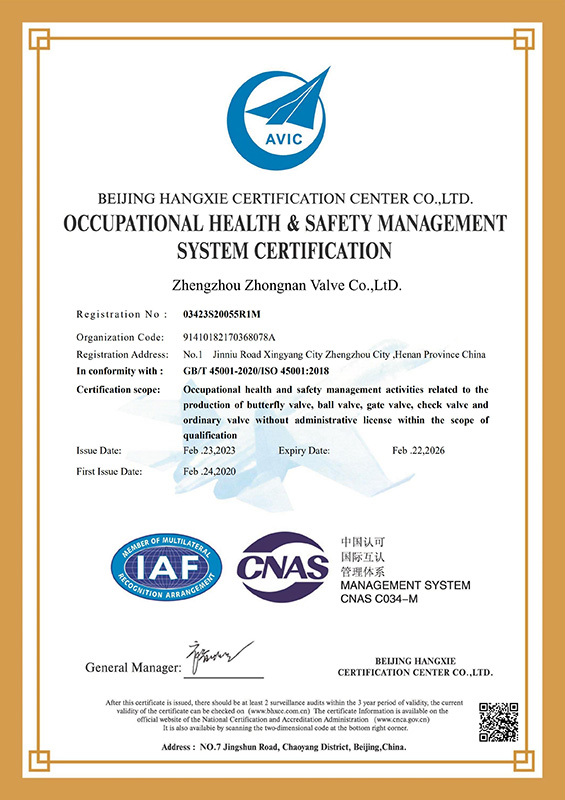

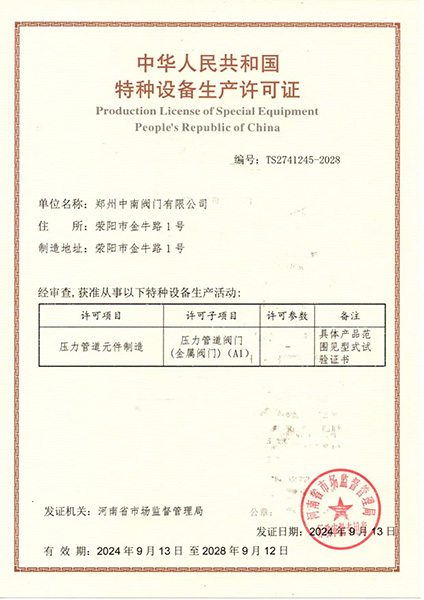

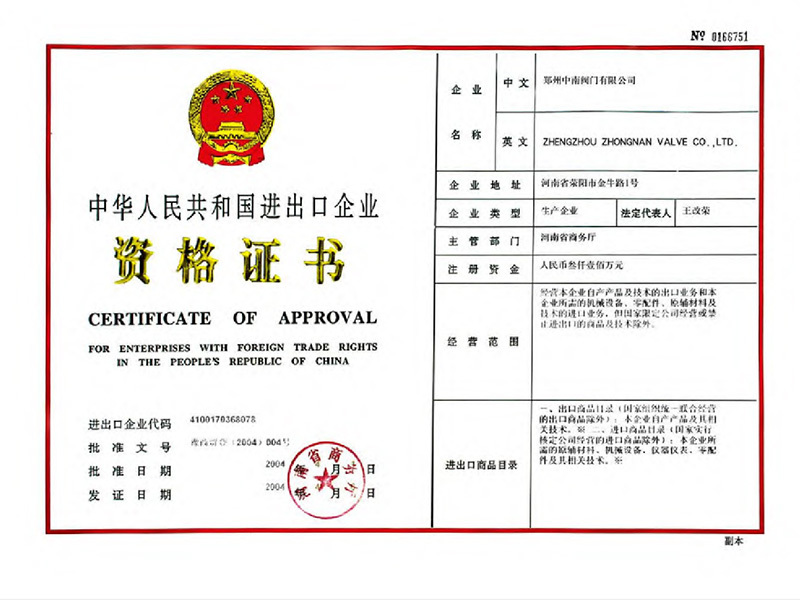

Honour